Digital Fabrication

Techniques: 3D design, laser cutting

Honeycomb Pendant Light

Fabricated with laser-cut eucalyptus wood and assembled entirely without adhesives

Fabricated with laser-cut eucalyptus wood and assembled entirely without adhesives

Honeycomb Pendant Light: Process

Overview

For my first venture into laser cutting, I was asked to create a lamp out of wood, without using any form of adhesive.

For my first venture into laser cutting, I was asked to create a lamp out of wood, without using any form of adhesive.

Precedent Research

As this project was my first time exploring laser cutting as a medium, I spent some time researching the techniques employed by other artists. I found myself drawn the most to works which balanced geometric and naturalistic forms, as well as those that managed to imbue heavy wood with a sense of lightness and delicacy.

As this project was my first time exploring laser cutting as a medium, I spent some time researching the techniques employed by other artists. I found myself drawn the most to works which balanced geometric and naturalistic forms, as well as those that managed to imbue heavy wood with a sense of lightness and delicacy.

Ideation

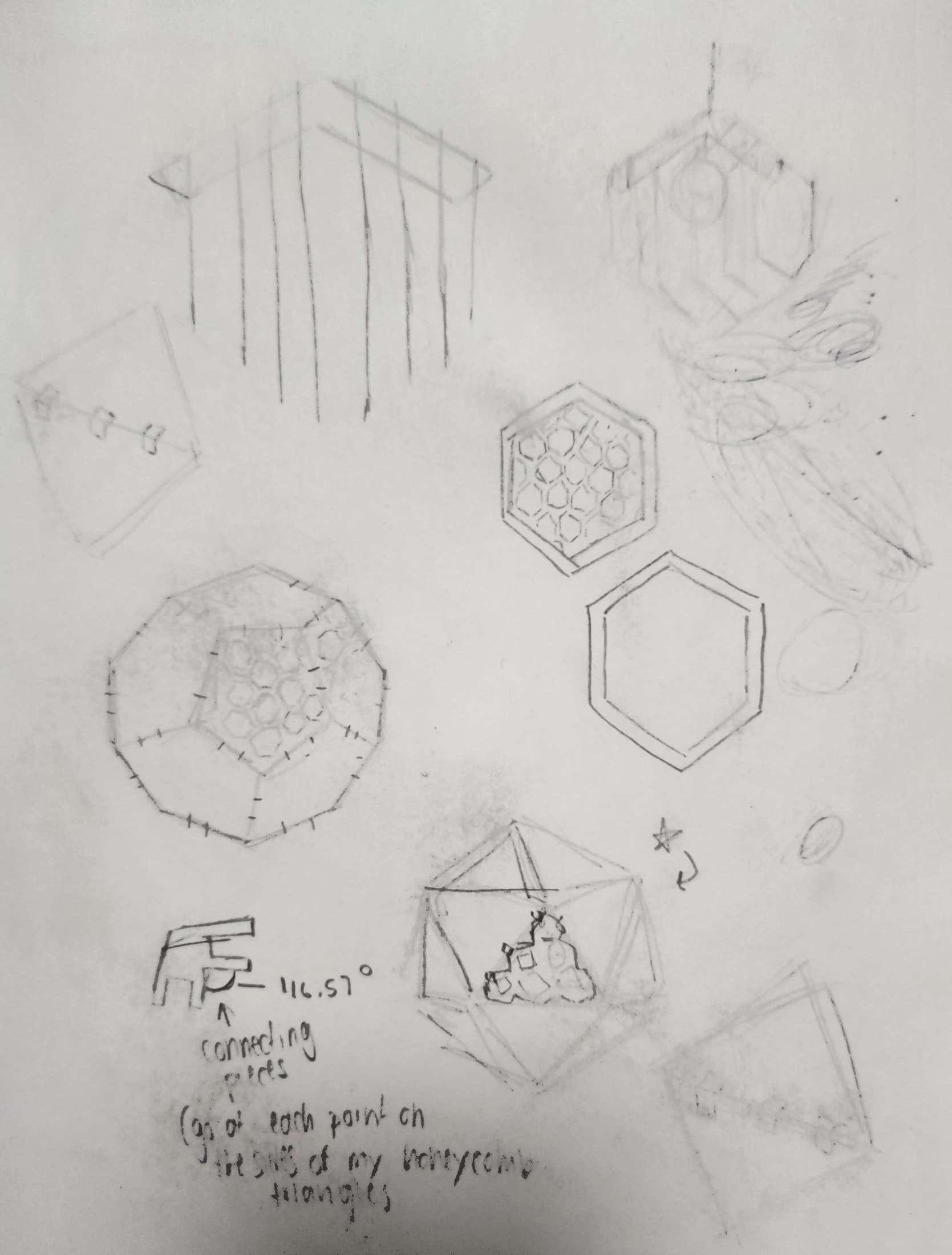

My visual research led me to consider how the projects I liked the most managed to imbue wood with a sense of lightness and delicacy. I settled on the honeycomb as a motif for my own lamp, and explored different ways of using a latticed panels to construct a geometrically interesting overall form.

My visual research led me to consider how the projects I liked the most managed to imbue wood with a sense of lightness and delicacy. I settled on the honeycomb as a motif for my own lamp, and explored different ways of using a latticed panels to construct a geometrically interesting overall form.

Construction

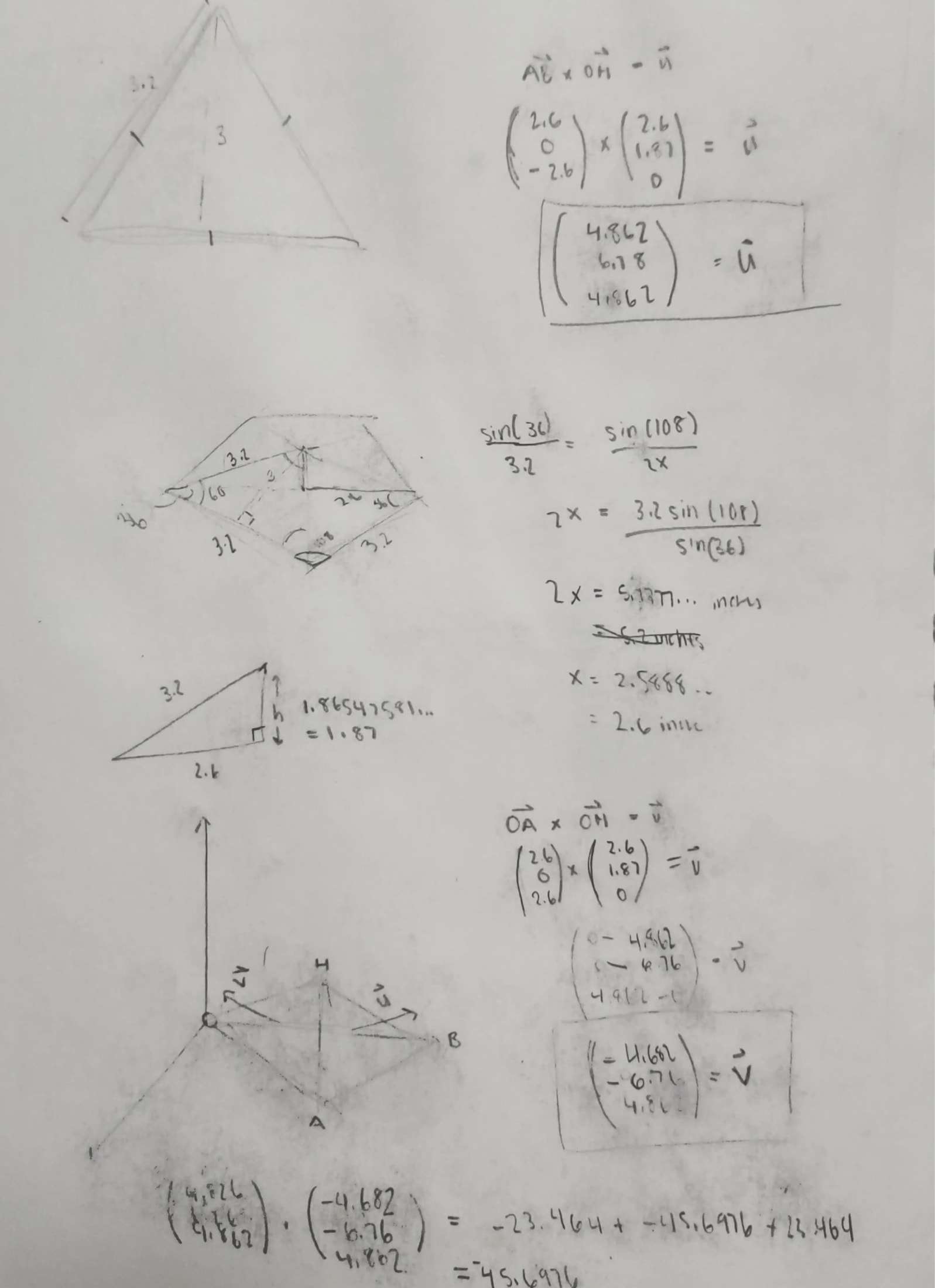

I decided that each panel would be secured to its neighbours by small connecting pieces, which I aimed to keep as unobtrusive as possible, as to not detract from the light, airy feeling of the form. This required me to calculate the dihedral angle, the angle at which two adjacent planes intersect. Using measurements from my Rhino file, I was able to calculate the theoretical normal vectors of two adjacent planes. By taking the dot product of these two vectors, I was able to calculate the angle between them.

My first attempt at laser cutting and building the lamp, however, was not successful. Though my calculations gave me a theoretical approximate of what the angle between each face should be, they failed to take into account the kerf of the laser and variation in dimensions due to the warping of the wood. I made small adjustments to my Rhino file, and tried again. By the third attempt, I was able to finally construct the lamp.

I decided that each panel would be secured to its neighbours by small connecting pieces, which I aimed to keep as unobtrusive as possible, as to not detract from the light, airy feeling of the form. This required me to calculate the dihedral angle, the angle at which two adjacent planes intersect. Using measurements from my Rhino file, I was able to calculate the theoretical normal vectors of two adjacent planes. By taking the dot product of these two vectors, I was able to calculate the angle between them.

My first attempt at laser cutting and building the lamp, however, was not successful. Though my calculations gave me a theoretical approximate of what the angle between each face should be, they failed to take into account the kerf of the laser and variation in dimensions due to the warping of the wood. I made small adjustments to my Rhino file, and tried again. By the third attempt, I was able to finally construct the lamp.